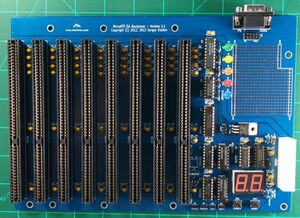

ISA Backplane

MicroATX ISA Backplane - Version 1.1.x

This backplane supports bus width up to 16 bits. It has onboard POST code indicators as well as a -5V regulator allowing you to use it with modern power supplies.

Contributions Welcome

If anyone reading this page is interested in contributing content please send me a text message at 3476042083 with your email address and I will send instructions on how to setup an account.

Assembly Video

[This video] shows how to put together the kit.

Features

- ATX Power Connector

- 16 Bit ISA bus

Required Tools

- Soldering Iron,

- Rosin core solder

- Wire cutters

- Pliers

- Multimeter (optional: if you want to check for shorts)

Assembly Steps

Start with the shorter components first. This way you can lay the board down flat on the table and be able to solder them in. The taller components go next. The recommended order is as follows.

1. IC Sockets

| component type | reference | Name | Qty |

|---|---|---|---|

| socket | U5, U6, U7 | 14 pin 300 mil DIP socket | 3 |

| socket | U1, U2 | 16 pin 300 mil DIP socket | 4 |

| socket | U3, U4 | 20 pin 300 mil DIP socket | 2 |

2. Capacitors

| component type | reference | Name | Qty |

|---|---|---|---|

| PCB | PCB | 1 | |

| Capacitor | C1 - C51 | 10 uF ceramic, 5.08 mm lead spacing | 51 |

| Capacitor | C52 | 1 uF ceramic, 5.08 mm lead spacing | 1 |

| Capacitor | C53 - C59 | 0.1 uF ceramic, 5.08 mm lead spacing | 7 |

Polarity doesn't matter unless you are using electrolytic ones.

3. ISA Slots

| component type | reference | Name | Qty |

|---|---|---|---|

| Connector | BUS1 - BUS8 | Edge Connector 98 Pin | 8 |

4 LED Lights

| component type | reference | Name | Qty |

|---|---|---|---|

| Diode | D1 - D5 | 5 mm LED | 5 |

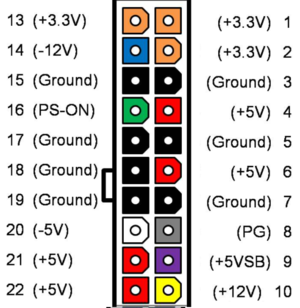

5 ATX Power connector

Board connector as it would appear looking down on the board. The plastic tab will be on the left side towards the inside of the board.

Note also the power connector pins will need to be bent slightly with pliers as the pin spacing on the PCB is a little wider than the power connector spacing.

| component type | reference | Name | Qty |

|---|---|---|---|

| Connector | P3 | ATX Connector | 1 |

LED Display Configuration

The ISA Backplane board supports a variety of 7-segment decoders and common anode / common cathode type LED displays. Please use the following table to determine the proper jumper pin configuration for J2 J3 and J4

7-Segment Decoders and Matching Displays

The one in bold is the one currently sold with the kit. Please check below for proper jumper settings for this decoder.

| 7-Segment Decoder Type | Hexadecimal Support | Matching Display Type | J2 | J3 | J4 | Built in current limiters 1 |

|---|---|---|---|---|---|---|

| 74LS47, 74LS247 | Limited - Displays distinct figures for codes A-F | Common anode | 2-3 | 2-3 | 2-3 | No |

| 74LS48, 74LS248 | Limited - Displays distinct figures for codes A-F | Common cathode | 1-2 | 2-3 | 2-3 | No |

| CD4511, MC14511, 74HCT4511 | No - Displays nothing (blank) for codes A-F | Common cathode | 1-2 | 2-3 | 1-2 | No |

| Mitel MD4311BE | Yes | Common cathode | 1-2 | 2-3 | 1-2 | No |

| DM9368 | Yes | Common cathode | 1-2 | 1-2 | 2-3 | Yes |

| DM9370 | Yes | Common anode | 2-3 | 1-2 | 2-3 | No |

| DM9374 | Limited - Displays distinct figures for codes A-F | Common anode | 2-3 | 1-2 | 2-3 | Yes |

| D345D | Yes | Common anode | 2-3 | 1-2 | 2-3 | No |

| D346D | Yes | Common anode | 2-3 | Trim2 | 2-3 | Yes |

| D347D | Limited - Displays distinct figures for codes A-F | Common anode | 2-3 | 1-2 | 2-3 | No |

| D348D | Limited - Displays distinct figures for codes A-F | Common anode | 2-3 | Trim2 | 2-3 | Yes |

- No need for current limiting resistor arrays (RR1, RR2), two 470 Ohm resistors should be used to limit current for the decimal point segment.These resistors should be installed between pins 8 and 9 of RR1 and RR2 or a DIP 16 isolated resistor arrays could be used.

- For decoders D346D and D348D the RV1 trimmer should be installed instead of the J3. This trimmer is used to adjust the intensity of the LED display.

ISA Bus

Click on the image to the right to see detailed 16 bit ISA bus pins.

Post Assembly & Cleaning

Once you have your board assembled you will need to clean the flux off the board. Depending on the flux you used some flux can remain conductive and result in computer glitches.

I have found the following procedure to be very effective in cleaning the board of any type of solder flux.

- Spray WD40 on the back of the board (not kidding).

- Scrub it in both the x and y direction with an old tooth brush.

- Then rinse with water scrubbing it with the toothbrush. Try not to get water on the front side. Little water is okay.

- Then use dish washing detergent with the brush to remove the WD40.

- Perform the final rinse.

- Use a hair dryer to to dry the board and let the board dry for 24 hrs.

Power On and Test

The goal is to identify any short circuits that would cause problems. Before powering on the device check to see if there are shorts across any of the rails of the PCB.

- Turn on the backplane and use a volt meter to check voltage across the PCB including the expansion slots.

- Plug in the ATX power connector and the PCB and the standby light should go on.

- Then click the power button and the power lights should go on.

- The -5V regulator is option and if your power supply does not provide -5V then you can solder that in as well. Once the regulator is installed the -5V light should go on as well.

Available For Sale

- Bare PCB

- Individual Components

- Full Component Kit